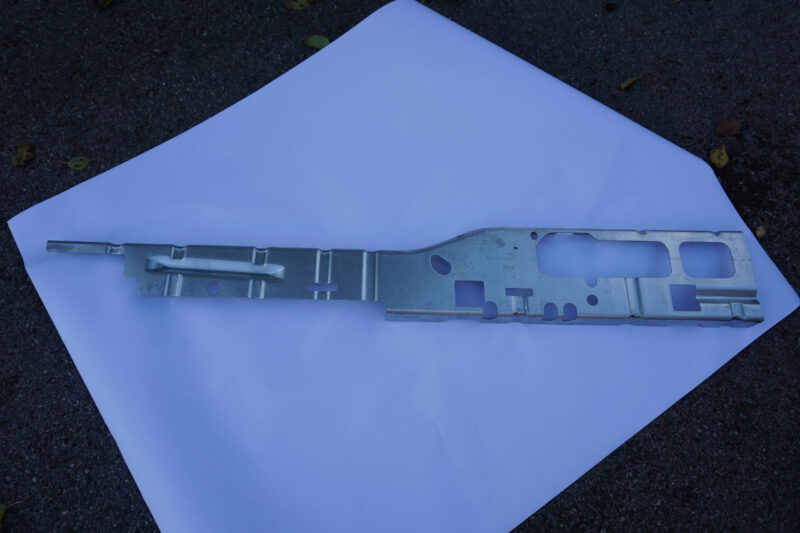

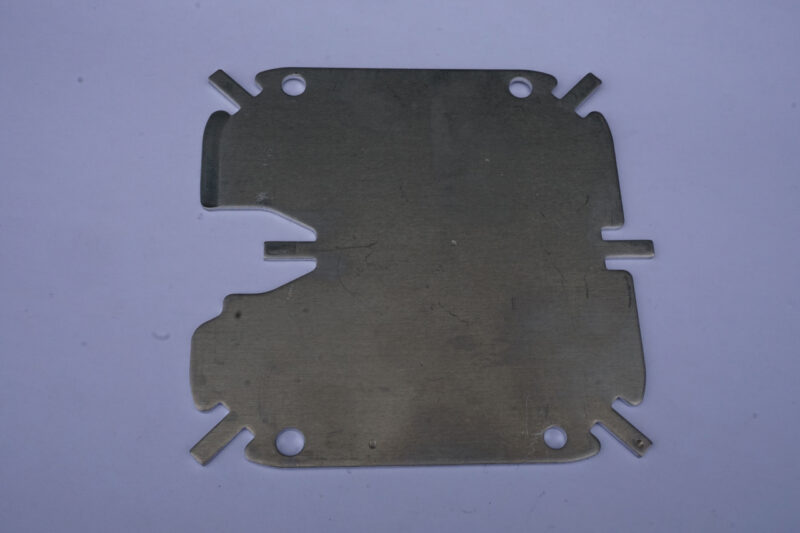

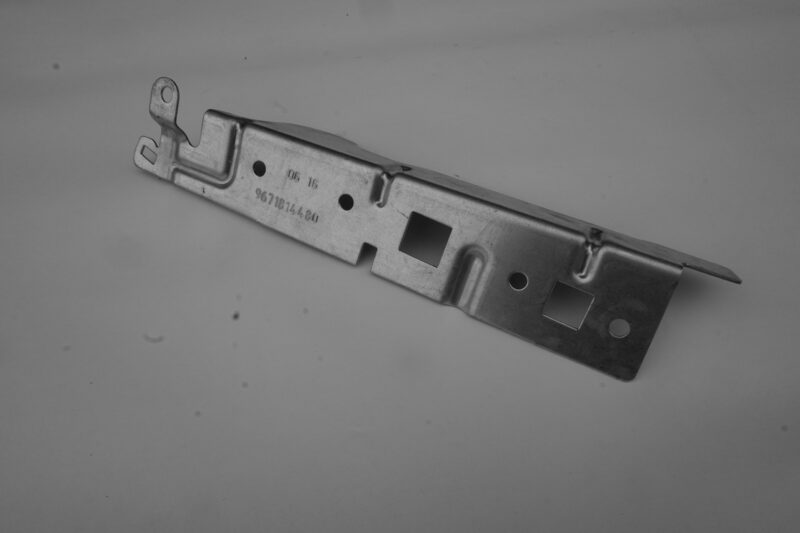

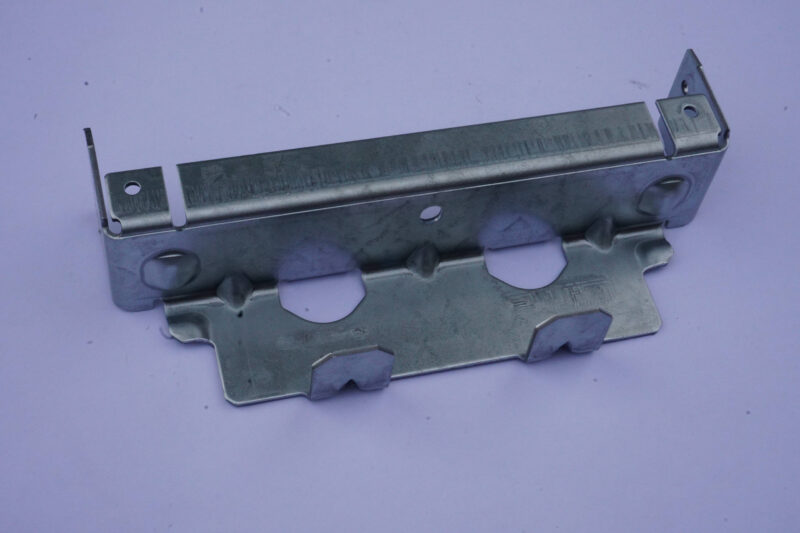

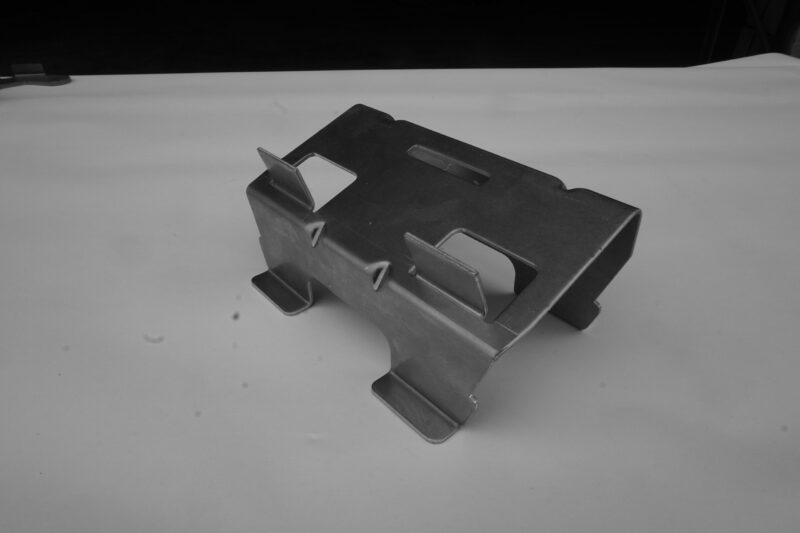

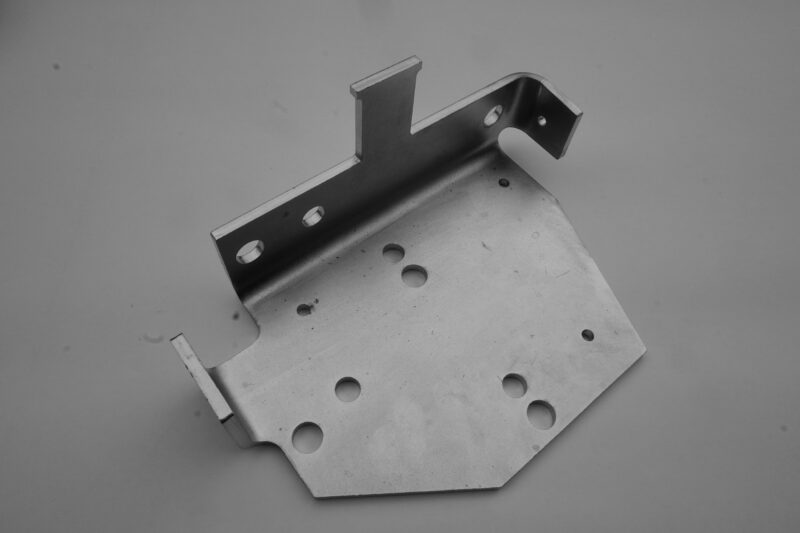

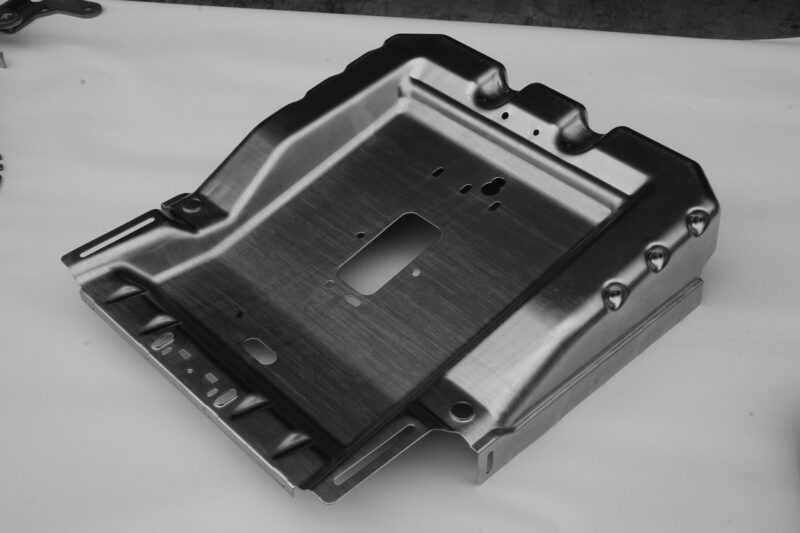

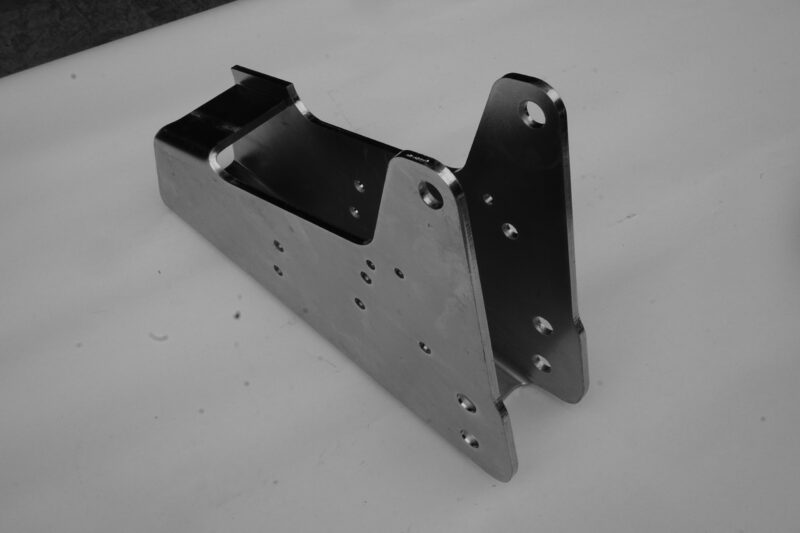

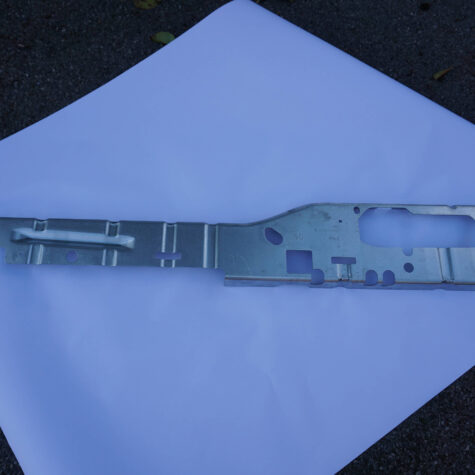

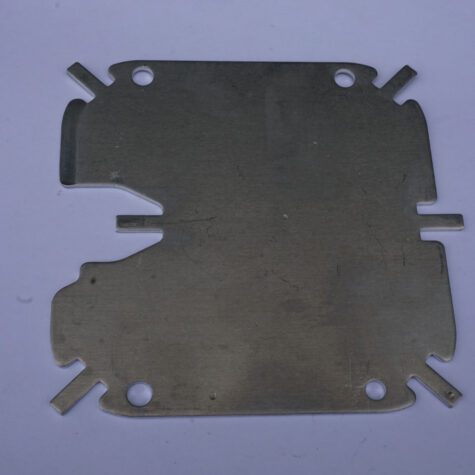

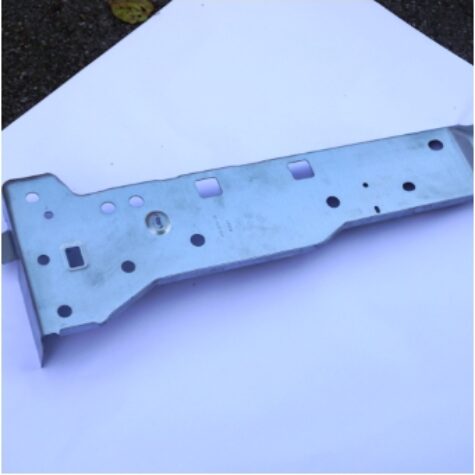

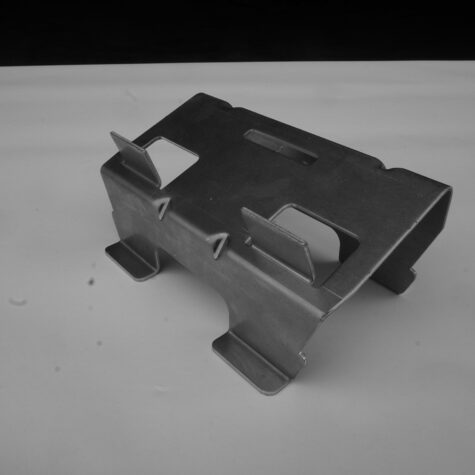

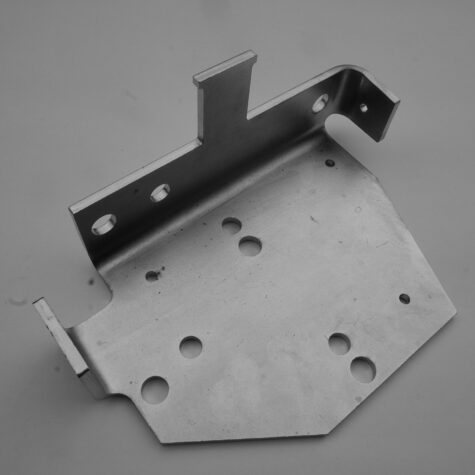

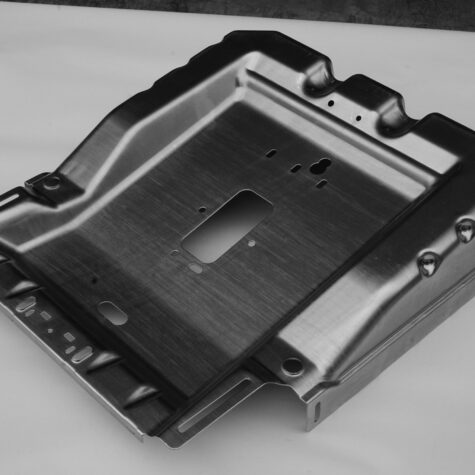

The stamping and bending process has been our core business for over 75 years. We have significant production equipment to manufacture your parts. Our presses have capacities from 100T to over 2000T. They can work with manual, progressive (https://en.wikipedia.org/wiki/Progressive_stamping) and transfer tools. (https://en.wikipedia.org/wiki/Transfer_stamping). The largest press tables are 6000x2500mm.

We have 30T bridges for handling tools. We process more than 20,000 tonnes of metal annually, of which 60% is high strength steel, 25% is classic steel and 10% is stainless steel. More than 50% of the processed steel has a thickness of more than 3mm.

We procure more than 60% of our steel in Germany, the rest comes from France and Belgium.

The quality of the parts produced depends not only on the quality of the machines and steels, but is also heavily dependent on the training of each member of our team. That is why we promote internal training by applying the TWI (Training Within Industry) programme (https://fr.wikipedia.org/wiki/Training_Within_Industry )